SPS Italia in Parma stands as a pinnacle for Italy's smart, digital, and sustainable industry. From

May 28 to 30, 2024, Dunkermotoren and MAE, both AMETEK brands, will grace

Hall 5, Stand L005, as steadfast partners of the Italian industry, impressing with their renowned quality and adaptability. Among their offerings, Dunkermotoren will unveil the

PLG 75 ServoLine gearbox, boasting a service life exceeding 20,000 hours, ideal for long-lasting DC motors. This comprehensive motor-gearbox solution thrives in applications with high cycle rates, distinguished by reliability, robust torque, and remarkable efficiency.

Nexofox, the Dunkermotoren IIoT brand, will also take center stage, showcasing its latest breakthrough. Explore the foundation for your smart factory with NexoLink, a novel module facilitating seamless integration of all smart Dunkermotoren motors. NexoLink's modular extensions, such as Smart Diagnostics and Predictive Maintenance, enable sensor-free monitoring of gearbox wear, serving as a vital indicator of overall service life. Nexofox is rapidly advancing in the hardware sector. In addition to the existing BGE 5510 dPro external controller, the BGE 8060 dPro now joins the controller family as a formidable addition."

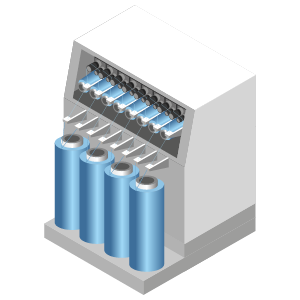

At SPS Italia,

Dunkermotoren emphasizes its

smart BLDC motor series dPro, ranging from 20 to 5000 W, featuring

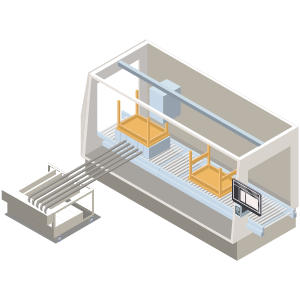

bus and Ethernet interfaces such as CANopen, PROFINET, EtherCAT, and Ethernet/IP. A notable highlight is the PROFINET Showcase, demonstrating the synchronous operation of four axes powered by BG dPro PN motors.

Since mid-2023, Dunkermotoren's product lineup includes the

NG 1000 WO hub gearbox, providing further development possibilities for driverless transport systems (

AGVs and AMRs). When paired with the BG 95 dPro, this solution stands at a mere 95 mm in height and, thanks to axle offset, enables vehicles with a minimum width of only 600 mm and a potential total weight of four tons. Versions with reduced gear backlash allow exceptionally precise vehicle positioning. Moreover, the availability of low-noise gearbox versions extends the applicability of mobile and self-propelled equipment, catering the requirements in the medical sector, such as mobile MRI or X-ray machines.

Dunkermotoren's solutions are particularly suitable for omni- or multidirectional vehicles. A compact and intriguing solution from TEKNO M.P., ideal for 360° continuous rotation, is showcased at the booth.

Dunkermotoren´s sister company, MAE, focuses on another critical trend: local sourcing. MAE fully embraces this trend, manufacturing its products exclusively in Europe. Thanks to the option to add brakes, encoders, gearboxes, and electronics,

MAE's stepper motor portfolio offers flexible integration into diverse applications. The newly integrated sGo electronics provide a cost-optimized control solution for Nema 17 and Nema 23 sizes.

Downloads:

![Motors for Wood industry Motors for Wood industry]()

![Motors for Printing industry Motors for Printing industry]()

![Motors for Textile industry Motors for Textile industry]()

![Motors for Plastics industry Motors for Plastics industry]()